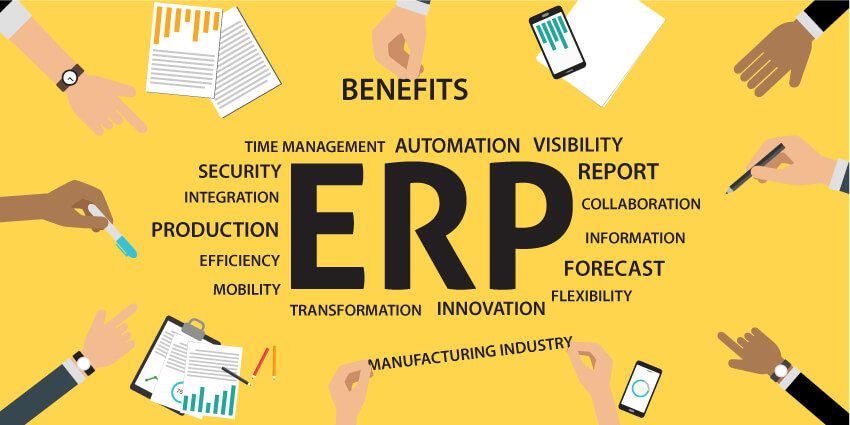

What Are the Benefits of Manufacturing ERP in the UAE?

Best ERP software in dubai

Innovation is an essential mix with agility and efficiency, to address the constant change of the manufacturing business scene. The intersection between these two factors is very significant for manufacturers in the United Arab Emirates (UAE), thus becoming a double-sided coin with both risks and benefits. Step into Enterprise Resource Planning (ERP) systems, a commanding set of tools that will help you manage different operations, bring order into the process by showing visibility, and increase business value. Through this profound blog post, we will look into the Best-in-Class ERP Systems in UAE and the advantages that Manufacturing ERP holds to business, ensuring a sustainably successful enterprise.

1. Enhanced Operational Efficiency:

• Streamlined Processes:

Manufacturing ERP integrates with Efficiency with the Best ERP Solution in the UAE and core functions of order, produce, and distribute the customers’ products as well as parts into one platform. As a result, bureaucratic processes become much less cumbersome with the manpower intervention work which makes errors disappear and workflow then speeds up.

• Real-time Data Access:

Thanks to ERP, stakeholders are able to obtain vital data immediately of good quality that supports their decision-making based on facts. This up-to-date knowledge base of stock levels, production schedules and resource coordination equips teams to take efficient corrective actions when bottlenecks occur.

- Automated Workflows:

A significant task of the best accounting software in uae automates and encompasses repetitive operations like order processing and inventory management which are freed up for more effective utilization of resources. By automating, we not only increase efficiency in our operation, but the employees will also be able to focus on the areas of innovation and customer service.

2. Improved Supply Chain Management:

• Seamless Integration:

With the advent of the complex international business environment, the modern management of the supply chain is crucial. The erp software dubai for manufacturing is the one that creates a smooth connection between the suppliers and thus, makes collaboration irrespective of market fluctuations, demand forecasting and inventory optimization possible.

• Demand Planning:

With the use of historical data and market trends in conjunction, erp software uae are able to plan out demand fluctuations, making the prediction of demand fluctuations much more accurate. Consequently, this proactive approach to demand planning is highly important because of such reasons as stockouts minimization, excess inventory reduction, and customer satisfaction enhancement.

• Logistics Optimization:

Taking the advantage of the ERP, the logistics operations can be substantially improved, e.g., by route optimization or freight management. By the way of isolating ineffectiveness and via using information-based decisions manufacturers can tie their supply chain networks together, and cut the transportation costs at the end.

- Enhanced Quality Control:

• Standardized Processes:

With manufacturing ERP all the processes and quality control measures are standardized and implemented in and throughout the enterprise. Through adherence to the standards of product specifications and procedures of production ERP keeps its high quality rating, while also meeting regulatory requirements.

- Real-time Monitoring:

The manufacturers have ERP in place. Therefore they can see clearly what is happening in real time during different stages of the production process. This permits the granular visibility of quality issues so that they can be proactively identified and this way subsequent interventions can be issued to prevent defects and rework. The benefits of cloud-based erp software in UAE allows for market trends to be addressed swiftly.

• Traceability and Compliance:

ERP systems allow manufacturers to trace the entire supply chain, from raw materials to finished products. It is done help to track components and other elements. This tracing, not only improves quality control, but it is also a prerequisite for the applicability of the standards and mandatory rules of the industry.

4. Strategic Decision-Making:

• Data-driven Insights:

ERP systems in manufacturing unite information from several sources, allowing the enterprise to gain comprehensive view of the business performance. By means of advanced analytics and graphical output tools, senior executives can obtain the required data for taking decisions on such important aspects as production efficiency, resources usage, and profitability.

• Scenario Analysis:

The best erp software in dubai helps a manufacturing company evaluate different strategies and possible scenarios as well as it provides simulation models to predict the effectiveness of chosen strategies. The actors replacing real-life events will allow the stakeholders to get a clear picture of the situation and to make decisions to minimize the risks, to create new income sources and to ensure the long-term development.

• Agility and Adaptability:

Today’s business is a dynamic environment where the ability to move quickly is of vital importance in succeeding. Manufacturing ERP helps companies gain the capacity to tailor their operations to the dynamic market setting in terms of the customers’ needs and regulatory requirements. The ability to perform the routine operations, for instance, scaling up of operations, entering new markets, and launching innovative products is well taken care of with the systems that give the required agility to remain ahead of the pack.

- Innovation and Product Development:

- Research and Development (R&D):

The Manufacturing ERP systems helps in keeping the R&D initiatives well on track by giving support tools of project management, resource allocation and collaboration. Through the leveraging of various tools and resources, manufacturers are able to abridge the R&D process and achieve faster time to market which results in quicker introduction of new products.

- Product Lifecycle Management (PLM):

Manufacturing ERP links up with PLM software to take control of the whole product lifecycle management process from the production to the retirement. This integration of efforts guarantees that all product development, manufacturing and marketing, promotional activities are subject to perfect alignment that ultimately results in optimized portfolios and improved market share.

• Collaboration and Ideation:

Manufacturing ERP motivates team effort and imagination through the creation of a centralized space where people from different departments can contribute suggestions, approve and also share knowledge. A teamwork culture that is nurtured by the manager to foster a problem-solving environment as individuals are encouraged to actively participate in the improvement strategy.

Conclusion:

The fact of the matter is that only the companies that adapt to the changing environment of manufacturing in UAE and accept the technology will stay profitable. Manufacturing ERP, in this sense, offers a complete set of tools and functionalities to anybody who wants to optimize their production, manage the supply chain, improve the quality control, and run the business in strategic terms to the satisfaction of the clients. Applying ERP, we can fully control and take charge of the business. Manufacture ring industries in the UAE can unlock greater levels of productivity as well as agility, and growth, positioning themselves for success in this digital age.